Catalog

API 6A Products

API 16C Products

API 6D Products

Positive choke

Features

• Pressure rating: 2K, 3K, 5K, 10K and ANSI classes up to 4500.

• Field conversion kits from positive to adjustable choke and vice a versa.

• Bonnet nut with vent hole for safety during servicing.

• Body/bonnet materials include, carbon steel, alloy steel, stainless steel and duplex stainless steel to suit different applications.

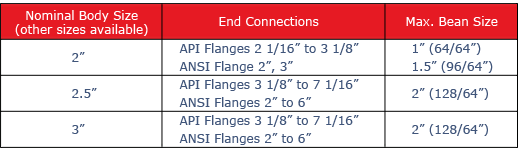

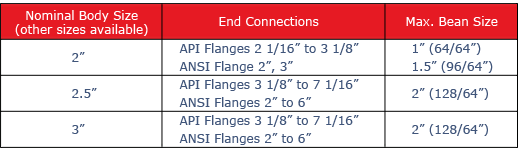

Bean size

Bean size

Increment between bean size diameters of 0.4 mm (1/64 in) to 50.8 mm (128/64 in).

Different material of construction of Beans

• Stainless steel • Stellite lined • Ceramic lined • Tungsten carbide lined

Basic construction of beans for Fixed Bean Choke

Gas Lift choke

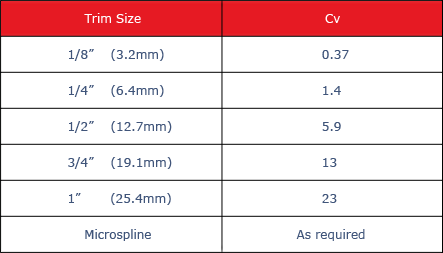

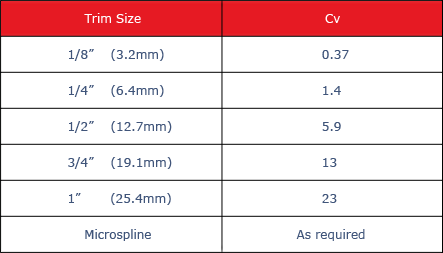

Gas lift flow control valves are being made both in-line and angle body configuration with flange, threaded or weld end connections.

With a range of trim sizes and materials, these valves use a profiled plug moving into a seat to vary precise flow range thereby providing fine flow control.

JVS control valves have become the valve of choice in many gas lift installations.

Feature

• Body: in-line or angle.

• End connections: flanged, threaded or weld end.

• Connections: 1", 2",3" from ANSI 150# up to API 5000.

• Trim in stainless steel, hard facing or tungsten carbide.

• Profiled trim to provide linear characteristics.

• Adjusting handle to provide continuous control.

• Indicator barrel shows valve setting in 1/64".

• Valves can be automated with electric or pneumatic actuators.

• Custom engineered microspline trims provide control below Cv+0.01 and maybe

interchanged in standard bodies.

Standard Feature

Following Gas Lift Choke of different sizes and pressure ratings have been manufactured & supplied.

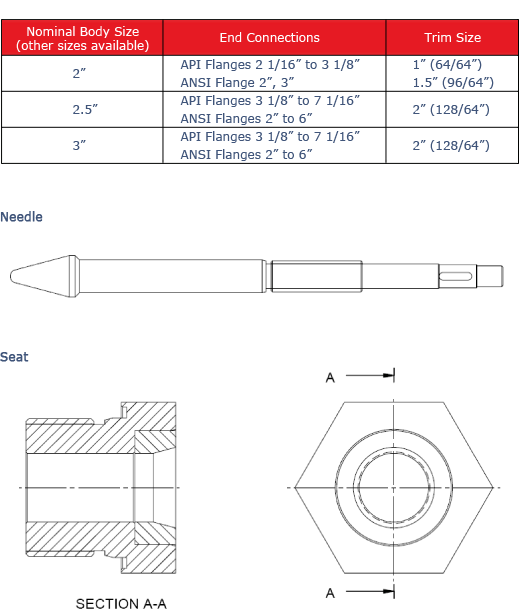

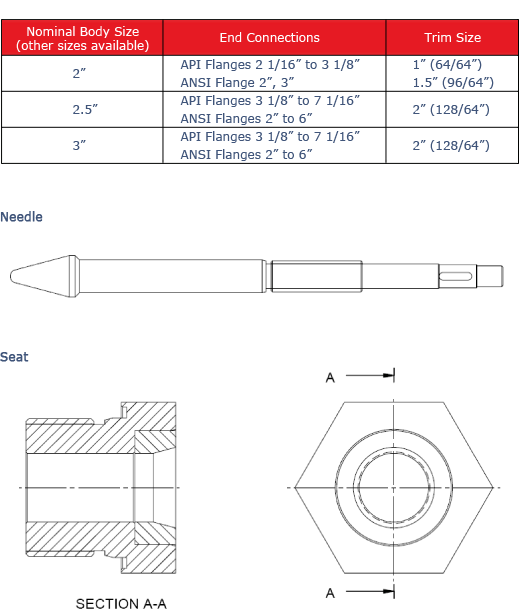

Needle & Seat choke

Features

• Pressure rating: 2K, 3K, 5K, 10K and ANSI classes up to 4500.

• Bonnet may be hammer union or bolted type.

• Bonnet nut with vent hole for safety during servicing.

• Dynamic seal (stem packing) uses spring energized seals.

• Micrometer indicator barrel calibrated in 1/64" 'Bean Size'.

• Body/bonnet materials include carbon steel, alloy steel, stainless steel and duplex stainless steel.

• In-line or angle body options.

Anti Cavitation choke

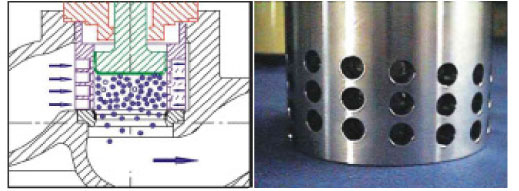

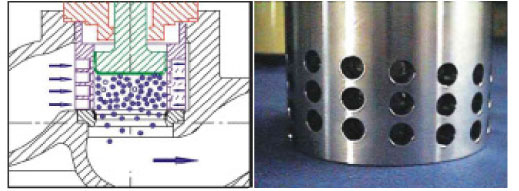

Trims utilize 2 or more ported cages to reduce pressure in stages.Cages are shrink fitted with each other in line with designed flow path. These trims are used primarily in anti cavitation service for water injection and water dumping.

By using a special retainer that controls where the cavitation takes place, it is possible to prevent serious damage occurring to the components provided the conditions are not too severe.

Three methods of combating cavitation

• Increase the life of valve by making vulnerable components more wear resistant.

• Control where the vapor bubbles collapse keeping them away from the valve body and trim.

• Ensure that the internal pressure of the fluid does not fall below the vapor pressure eliminating the formation of vapor bubbles.