Catalog

API 6A Products

API 16C Products

API 6D Products

Multistage choke trim has been introduced to cope up with the significant pressure drop inherent in wellhead start up, whilst also providing minimal flow restriction during operation.

Multistage is most suitable for initial high pressure drop, low flow conditions which then change gradually to low pressure, high flow. It is a combination of disc & flow cage design with multi-hole geometry to handle tri linear characteristic.

The additional feature of above designated multistage is that the trim can be specified with control valves or retrofitted to existing valve bodies. In all cases, the multistage trim secures the valve seat without the use of a clamping cage and in turn increasing the seat bore to maximize capacity as well as through output.Developed based on years of practical experience of providing choke application solutions throughout the world. The multistage trim consists of two well-defined sections:

- The start-up section, comprising approximately the first 10% to 30% of travel, determined by the well pressure/flow profile. It directs the flow through ports designed to impart significant friction on the fluid, resulting into lower velocities and reduced pressure recovery characteristics.Valve noise,erosion and vibration are within acceptable limit. This will increase the operational life of the choke.

- The multistage is designed to overcome specific operating characteristics in wellhead and associated applications like sour gas production, high pressure crude oil production, water injection and similar application.

Plug head is always pressure balanced & provisions are made at bonnet to handle high pressure.

Velocity Control Trim (VVC)

• Splitting the flow into a large number of small streams reduces the energy levels in each stream

• Large trim surface area maximizes friction against the fluid

• Large number of changes of direction

• Repeated compression and expansion

Applications of VVC Chokes include

• High pressure gas letdown and production where high energy dissipation can cause damage, vibration and/or excess noise in a single stage trim

• Anti cavitation service in water injection,pressure balancing and water dumping

DISC STACK - VVC

• A Disc Stack is the "nick–name" given to a valve trim that reduces fluid pressure within the valve in a controlled fashion.

• It comprises of a number of manufactured discs that are assembled together to form a stack.

• But the term "stack" shouldn't limit us, trims must reduce pressure!

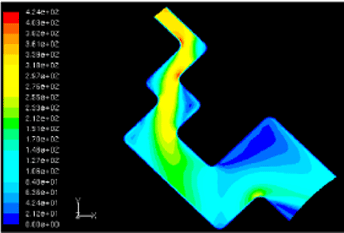

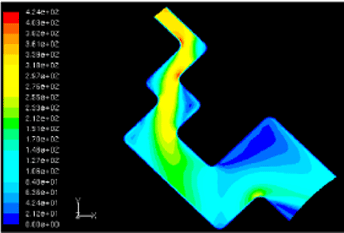

DISC STACK DESIGN

• Can be used for cavitation elimination on liquids and low noise on gases.

• Can handle very high pressure drops at high flows.

• Flow direction can be either over or under for liquids.

• Flow direction must be under the plug (i.e. inside to outside) for gases and vapours.

• The passageways in any disc are designed to handle the full pressure drop of the application but with only a small part of the total flow.

• The number of discs will determine the total flow capacity.

• In the pressure drop across the valve varies with flow then the discs will require a different design at the bottom, top and maybe in the middle.

SEVERE SERVICE APPLICATIONS