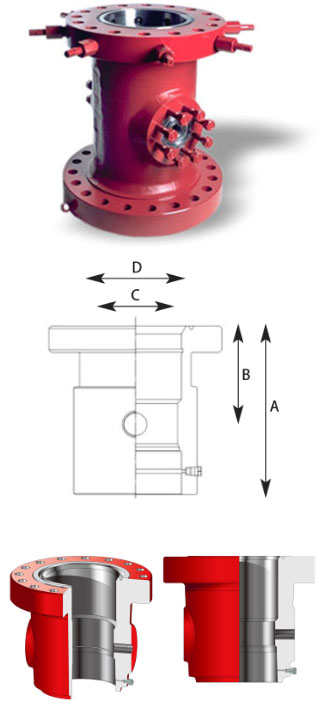

Description: The casing head is the lowest part of the wellhead assembly and is always connected to the surface casing string. It supports subsequent drilling wellhead and completion equipment.

Functions

◆ Provides for attachment to surface casing string.

◆ Supports blowout preventers while hole is drilled for next casing string.

◆ Provides for suspending and packing off the next casing string.

◆ Provides outlets for annular access.

◆ Provides for testing BOPs while drilling.

C-22

Features

◆ C-22 accepts C-21 non-automatic sealing casing hanger w/ type H seal ring, C-22 & C-122 automatic sealing casing hanger.

◆ C-22-BP-ET has bowl-protector lockdown screws in the top flange.

◆ C-22 eliminates the need for lockdown screws to retain bowl protectors.

◆ Bottom preparation can be either male-threaded, female-threaded,

slip-on weld or Slip Loc.

Benefits

◆ Straight bowl prevents wedge-locking of bowl protectors, casing hang

ers and test plugs.

◆ Seal bore less likely to be damaged during drilling.

◆ Detachable base plate available for C-22 heads provides time savings

and adds value due to better utilization of customer-owned property.

◆ C-22-EG reduces number of leak paths, lowers cost and increases safety

as there is no need to work beneath the BOPs.

C-29

Features

◆ C-29 offers same features as industry standard C-22 with the exception

of the EG option.

◆ C-29-ET has multiple lockdown screws in top-flange which retain the

hanger and can be used to energize the hanger packoff seal.

Benefits

◆ Deeper bowl accepts C-29/C-129/C-229/C121-S extreme-load casing

hangers in addition to other FMC Surface Wellhead casing hangers.

◆ The lockdown screws of the C-29-ET can also be used as bowl-protector

hold-down screws.